Cognex VisionPro Software

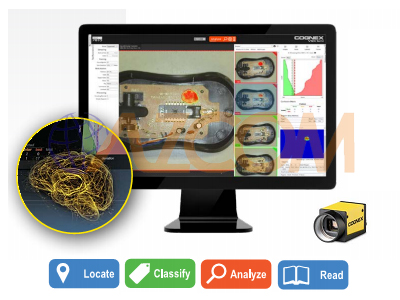

VisionPro® software is the leading PC-based vision software that empowers users to quickly set up and deploy even the most challenging 2D and 3D vision applications—no matter which camera or frame grabber they use.

Proven in more than 700,000 installations worldwide, the VisionPro tool library performs a wide range of functions from geometric object location and inspection to identification and measurement.

- Powerful vision tools (including PatMax®, LineMax™, OCRMax™ and IDMax®) perform accurate and repeatable inspections.

- With an extensive .NET class library and user controls, users can fully integrate VisionPro software into automation equipment.

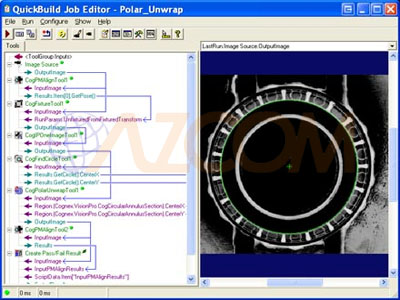

- Cognex Designer and VisionPro QuickBuild™ let you configure acquisition, select and optimize vision tools and make pass/fail decision without programming.

- Fully compatible with latest Windows® environments and supports Microsoft 64-bit operating systems to meet the demands of larger cameras and greater pixel depth.

- Supports a broad range of Cognex Industrial Cameras and most 3rd party cameras through the Cognex Acquisition Alliance program.

VisionPro Vision Software Vision Tools

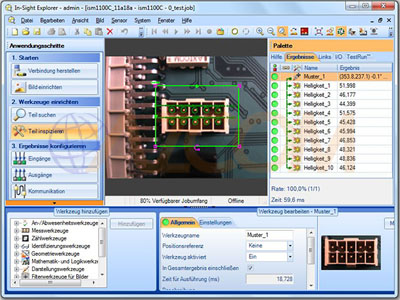

Beginning with the introduction of Cognex Designer software, Cognex Designer automatically includes the latest VisionPro software and capabilities. This enables users to take advantage of the graphical capabilities of Cognex Designer with the well-known and respected vision tools of VisionPro software, including PatMax®, IDMax®, and OCRMax®, and PatMax® AutoTune (introduced with Cognex Designer 2.0.)

Advanced computer vision technology

VisionPro® and Cognex Vision Library (CVL®) Power Tools have the intelligence to ignore non-critical variations in appearance while focusing on the critical features that determine a product’s acceptability. Power Tools do not require extensive image preprocessing to achieve the final solution, adding faster application development for the vision engineer and lower lifecycle costs for the company.

Geometric pattern matching and inspection

The patented PatMax® algorithm is the industry’s gold standard for part and feature location, providing accuracy and repeatability under the most challenging conditions.

Identification, OCR and OCV

1DMax® and 2DMax+ read even the most degraded Data Matrix codes, delivering consistently high read rates needed for part traceability. OCRMax™ provides high-speed optical character recognition and verification, even when the print is extremely distorted.

Color sorting, matching and monitoring

Find, measure/gauge, and analyze

Image processing tools

Optimize and manipulate images prior to inspecting the object. Distinct calibration tools for area and line scan cameras accurately correct lens distortion and camera displacement such as rotation and tilt.

3D Tools

Accurate, real-time, three-dimensional position information is used to automate challenging assembly verification, logistics, and robot applications in automotive and precision manufacturing industries.