Reaming SECO

REAMING

Our broad selection of high quality, easy-to-use reamers are perfect for advanced machining and large batch production.

These holemaking products range from 3 – 154.5 mm in diameter and feature optimized cutting grades and geometries for achieving high productivity in all workpiece materials.

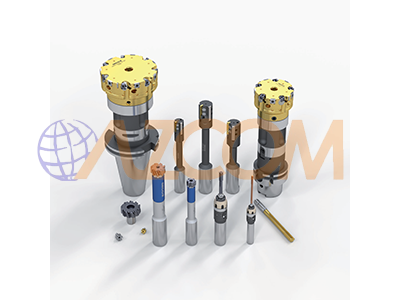

1. PRECIMASTER PLUS – EXCHANGEABLE HEAD REAMER

Precimaster™ Plus is a modular reamer system that boosts reaming speed, stability and versatility for more precise, cost-effective hole production.

Building on the success of the original Precimaster, the system features an innovative high-precision connection, solid-carbide disposable heads as well as common holders for blind and through-hole applications. Such enhancements enable size tolerances held to between 15 and 25 microns and surface finishes of Ra. 4 to Ra. 8.

The system’s patented connection ensures reamer head exchanges are fast and easy with repositioning repeatability and runout of under three microns. A special three-vertical-drive-pin design enables the connection to handle high levels of transmissible driving torque. Internal axial clamping forces draw the reamer heads up into the system shanks, creating a strong interface that maintains high precision.

Precimaster Plus uses solid-carbide disposable heads in diameters that range from 10 mm to 60 mm and mount to four standard shank sizes. Shank lengths are available in short, medium and long options to accommodate restricted clearance situations, common hole depths and up to 10 x D, respectively. Solid-carbide heads, when compared with traditional brazed-tip technology, allow for an increased number of cutting teeth on the same head diameters for up to 30 percent faster feed rates. Solid carbide also extends tool life by up to 30 percent, delivers increased stability for tougher materials and makes for a more cost-effective system.

For chip control and management, Precimaster Plus reamer shanks can apply different types of flushing for both blind and through holes. Tool body coolant outlets in the front force the chips up along the head flutes and out the blind holes, while standard through-tool coolant blasts the chips forward and away from the tool for efficient through-hole reaming.

Precimaster Plus features three lead geometries for universal, aggressive feed and fine finish operations as well as five reamer head grades, involving coated and uncoated carbide and cermet, to ensure optimised performance in all workpiece materials.

2. NANOFIX – SOLID CARBIDE REAMER

Nanofix Solid Carbide Reamers are designed for small diameters from 2.97 to 12.05 mm (.117″ – .474″).

These versatile reamers have internal coolant with a simple adjustable system so the outlet style can be set for either through or blind bore, depending on application. The Nanofix produces hole quality of IT7.

Featuring the patented Quick-Fit clamping system, Nanofix holds the entire diameter range with only two holders. This precise quick tool changing system reduces the time needed to change tools and eliminates the need to recheck the overall length and positioning when replacing reamer. Plus with only two shank sizes, only two sizes of Quick-Fit holders are needed thereby reducing the number of items in stock.

This multi-tooth solid carbide reamer is available in three geometries: EB45, EB845 and EB25. The range includes coated and uncoated grades. Nanofix is also available in a shorter length, which is great for lathe and compact applications.

3. BIFIX – SINGLE BLADE ADJUSTABLE REAMER

Bifix™ indexable blade reamers bring high-precision performance to all workpiece material groups. These products can achieve a hole tolerance of IT6 and a surface finish of Ra 0.25 thanks to three cermet guide pads and an accurate adjusting system.

These reamers are highly cost effective in that their indexable blades feature two cutting edges per blade. They are also extremely versatile thanks to their optimized geometries, various grade options and two coolant designs for producing either through holes (chips push forward) or blind holes (chips push backwards).

Production security is also a top priority for these reamers as they come with a strong clamping system as well as provide optimal chip evacuation via internal through-coolant channels.

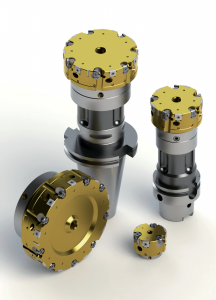

4. XFIX – LARGE DIAMETER ADJUSTABLE REAMER

Xfix™ large-diameter, multi-tooth reamers are all about bringing the highest possible performance and precision to hole production. And, thanks to a modular construction shank and extension program, they can achieve cutting depths up to 6.5xD within a diameter range of 39.5 – 154.5 mm.

These reamers are quick and easy to adjust. A precision manufactured insert pocket for the back taper requires no adjustment, while only one screw is required to set the diameter and secure the insert.

The patented pre-loaded guiding pads system used with these reamers guarantees the stability of the cutting process and ensures reliable tool life.

Xfix reamers come with inserts that have either four or eight numbered edges and take advantage of the latest in coatings technology for an overall cost-effective holemaking solution.

Four edges inserts are to be used when cutting long chipping material to guarantee optimal chip control. Eight numbered edges inserts will offer low cost consumable cost in short chipping cast iron.