Our team of advanced cutting materials experts is continuously looking for new ways to use PCBN, PCD and ceramics to develop Secomax™ cutting tools that bring exceptional productivity and tool life to the machining of difficult, highly abrasive materials.

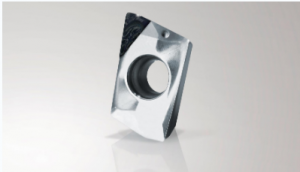

PCBN (Polycrystalline Cubic Boron Nitride)

This advanced material comes as a result of sintering micron cBN powders with various ceramic binders to create extremely hard and thermally stable cutting tools. Within this category, we have a wide variety of grades specifically developed for machining hardened steel, pearlitic cast iron, hard iron and superalloys.

PCD (Polycrystalline Diamond)

This advanced material has a level of hardness that is comparable to natural diamond. Within this category, we have several tools that can handle both hard and tough materials as well as plastics, graphite, copper and brass.

Ceramics

The high-speed capabilities of this advanced material result in metal removal rates that are four to eight times greater than carbide. Within this category, we have grades that offer optimized wear resistance and toughness in the machining of nickel-based heat-resistant superalloys.

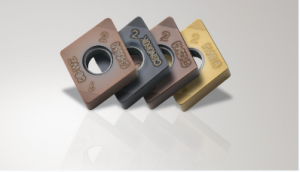

PCBN GENERAL TURNING – ISO INSERTS

We formulate our Secomax™ PCBN grades to significantly reduce production costs when machining hardened steel, pearlitic cast iron, hard iron and super alloys.

PCBN (polycrystalline cubic boron nitride) is an advanced material that comes as a result of sintering micron CBN powders with various ceramics to create extremely hard and thermally stable cutting tools.

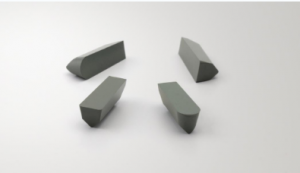

PCBN GROOVING AND PARTING-OFF INSERTS

Secomax™ PCBN grades for grooving and parting off significantly reduce production costs for applications in hardened steel, pearlitic cast iron, hard iron and superalloys.

PCBN (polycrystalline cubic boron nitride) is an advanced material that comes as a result of sintering micron CBN powders with various ceramics to create extremely hard and thermally stable cutting tools.

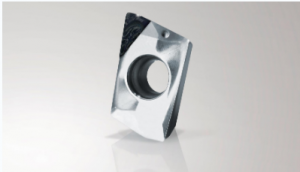

PCD GENERAL TURNING – ISO INSERTS

We formulate our Secomax™ PCD grades to significantly reduce production costs when machining aluminum alloys, titanium and other non-ferrous materials.

PCD (polycrystalline cubic diamond) is an advanced material that comes as a result of sintering together selected diamond particles at high pressure and temperature.

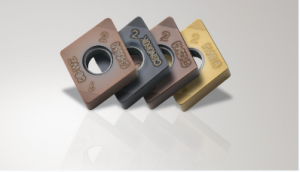

CERAMIC GENERAL TURNING – ISO INSERTS

Our Secomax™ ceramic insert grades provide optimized wear resistance and toughness when cutting parts from heat-resistant superalloys, such as Inconel, MAR, RENE, Nimonic and Waspaloy, at high speeds.

In fact, the high-speed capabilities of ceramics result in metal removal rates that are four to eight times greater than carbide. But to effectively utilize ceramic grades at high speeds, the workpiece setup and machining conditions need to be as stable as possible to prevent chipping of the grade.

CERAMIC GROOVING AND PARTING-OFF INSERTS

Our Secomax™ ceramic insert grades for grooving and parting off provide optimized wear resistance and toughness when working with heat-resistant superalloys, such as Inconel, MAR, RENE, Nimonic and Waspaloy, at high speeds. Effective application of these grades requires an extremely stable workpiece setup and machining conditions to prevent the possibility of chipping.

Bài viết liên quan: Đầu móc lỗ SECO