Catalogue – Hướng dẫn kỹ thuật

SECO drilling

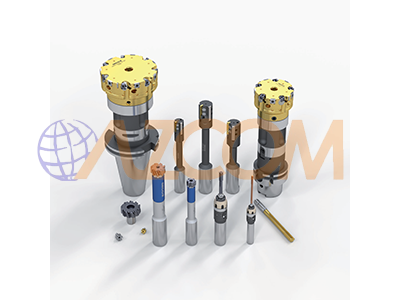

Seco has a full range of drilling products, including solid carbide drills, exchangeable tip drills and indexable insert drills. This wide portfolio of products provides solutions for all applications and workpiece materials across all industry segments, including automotive, energy, medical and more.

With optimized coatings, tip geometries and insert designs, Seco drills create high quality holes with high productivity.

Diameter range 0.1 – 160 mm (.004 – 6.299 inch) with hole tolerances from IT7 to IT12.

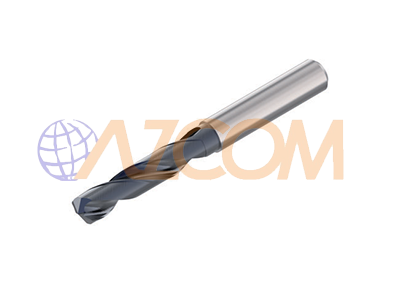

1. SOLID CARBIDE DRILLS

Incorporating a wide range of geometries, coating and diameters, Seco’s diverse portfolio of solid drills excels across a broad spectrum of workpiece materials, from steel to stacked composites and difficult-to-machine materials. With diameters as small as 0.1 mm (.003 inch), our range covers a comprehensive array of applications for varied industry segments, including medical and aerospace.

Optimized geometries provide options for challenging applications, including irregular exit shapes. With these tools you can use high feeds and cutting speeds and achieve close hole tolerances with geometries suitable for all workpiece materials.

Diameter range 0.1 – 20 mm (.003 – .787 inch) with hole tolerances from IT7 to IT12.

2. EXCHANGEABLE TIP DRILLS

Seco’s exchangeable tip drills incorporate geometries and coatings that ensure high performance and productivity, while minimizing cost by eliminating the need to regrind or replace drills. Additionally, the ability to change tips for different workpiece materials and application requirements reduces the amount of tooling inventory that must be kept on hand.

Diameter range 10 – 25.99 mm (.393 – 1.023 inch) with hole tolerances from IT9 to IT10.

3. INDEXABLE INSERT DRILLS

Seco’s range of Perfomax™ indexable insert drills features strong square inserts with four cutting edges, high drill body stability, a low friction coating, unique chip flute design and inserts with modern grades that use Duratomic® technology.

T250D is the first choice for heat resistant materials and inserts in this grade feature sharp cutting edges to minimize heat generation during the drilling process.

Diameter range 15 – 160 mm (.590 – 6.299 inch).