AI Camera Cognex In-sight 2800

Features

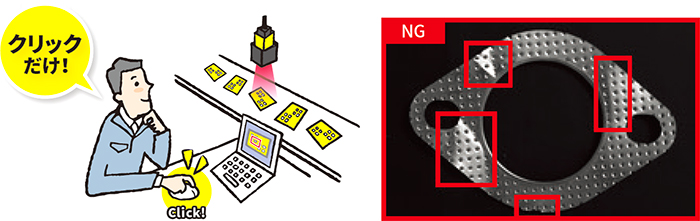

Anyway, anyone can use it easily

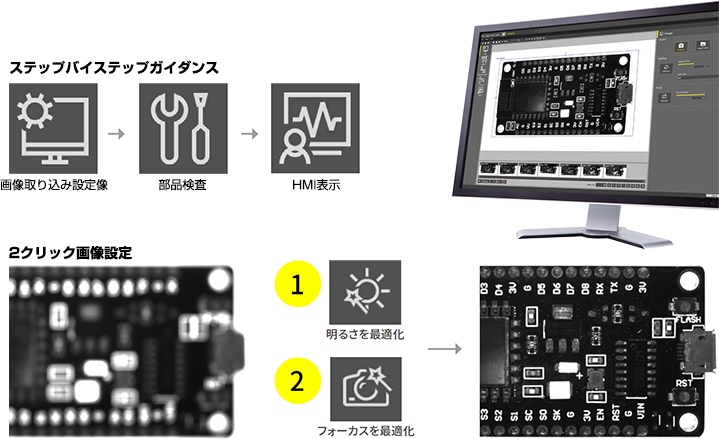

・The setting is completed in 3 steps. Quickly start shooting with an intuitive UI.

・No need to prepare a huge number of images.

・No GPU or programming language required. No image processing expert required.

・By switching lighting colors with multi-color lighting, it is possible to acquire the optimal image for any workpiece (optional).

Equipped with visual inspection, product type identification

, and deep learning ViDi EL tools that are one rank higher, visual inspection and product type identification are possible. No need to set parameters or thresholds.

・Best class image sensor. High resolution image acquisition of 1.6 million pixels (when applicable model is selected).

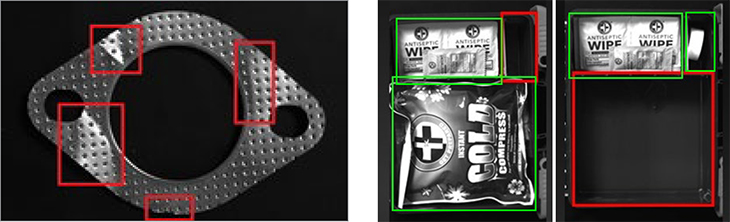

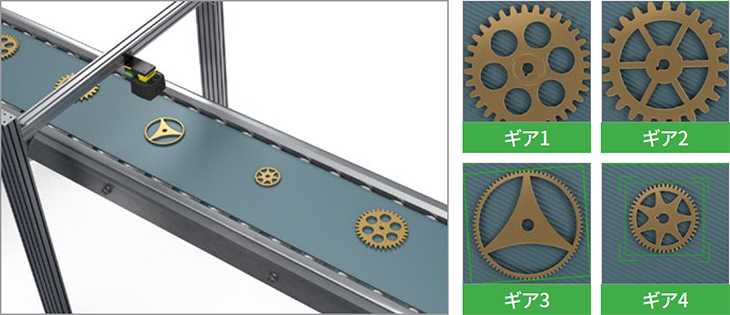

・Batch inspection of multiple locations within the field of view is possible. Flexible combination of inspection tools.

■ Automate inspections in minutes — no programming required

The In-Sight® 2800 vision system combines deep learning technology with traditional rule-based vision tools to solve a wide range of inspection applications.

From simple presence/absence inspections to complex sorting and sorting applications, the In-Sight® 2800 makes it easy to deploy error-proof solutions. Designed for factory automation, the In-Sight® 2800 enables manufacturers of all sizes to:

-

Improve product quality

The excellent recognition power of deep learning, which enables not only OK/NG judgment but also component classification based on defect types and user-defined features, detects minute defects with high accuracy.

-

Maximize operational efficiency

Quick and intuitive job setup saves line operation of image sensors. — No vision or deep learning expertise required.

-

Simplified system configuration

A modular solution of built-in illumination and lenses eliminates trial and error in choosing optical options. With just a few clicks of a button, you can decide the best configuration for your application.

■ Abundant set of tools that enable you to solve a wide range of problems

The In-Sight® 2800 is equipped with both rule-based and deep learning tools, and contributes to automation in all applications from error-proofing to inspection. In addition to using the tool alone, multiple tools can be combined to build more advanced judgment logic.

-

deep learning tools

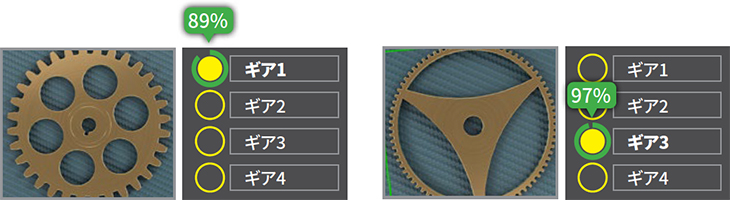

The In-Sight® 2800 is equipped with a ViDi™ EL Classify tool that utilizes deep learning technology, enabling deep learning learning on the device and outputting highly accurate results in real time.

-

study

The ViDi™ EL Classify tool can be used with 5-10 images per classifier and can be trained in less than 1 minute. No programming required.

-

credibility score

The judgment reliability of the deep learning learning model can be visually confirmed in real time without any operation, helping to build highly reliable inspections.

-

Multiple classification function

The ViDi™ EL Classify tool can perform not only two-type classification such as OK/NG, but also various classifications such as product type classification, sorting, and defect type classification by recognizing the characteristics of each part classification excluding individual variations. Enables higher levels of automation.

-

Rule-based vision tool

The In-Sight® 2800 is equipped with a well-established legacy vision tools library. Many functions are available, such as distance measurement, area measurement, counting, logic operation tools, etc.

-

Supports multiple-point inspection

Multiple inspection areas can be deployed within the field of view, and arbitrary inspection tools can be executed for each area.