Polyurethane tube SMC – TU/TIUB series

How to order

| TU0425 | BU | – | 20 |

TU0425: Tube type

BU : Color (1)

20: The length of each roll (2)

|

Tube size |

||||||||||||

|

Metric (TU series) |

Inches (TIUB series) |

|||||||||||

|

(1) Model |

TU0212 |

TU0425 |

TU0604 |

TU0805 |

TU1065 |

TU1208 |

TU1610 |

TIUB01 |

TIUB05 |

TIUB07 |

TIUB11 |

TIUB13 |

|

Tubing O.D. (mm) |

2 |

4 |

6 |

8 |

10 |

12 |

16 |

3.18 |

4.76 |

6.35 |

9.53 |

12.7 |

|

Tubing I.D. (mm) |

1.2 |

2.5 |

4 |

5 |

6.5 |

8 |

10 |

2 |

3.18 |

4.23 |

6.35 |

8.46 |

|

Fluid |

Water gas |

|||||||||||

|

Maximum operating pressure (Mpa) |

0.8 MPa (ở 20oC) |

|||||||||||

|

Pressure demolition |

Based on the table of overload characteristics and operating pressure |

|||||||||||

| Connector

|

Quick connector, Plug connector, Self-adjusting connector, Small connector |

|||||||||||

|

Bending radius (mm) |

4 |

10 |

15 |

20 |

27 |

35 |

45 |

10 |

15 |

23 |

27 |

35 |

|

Operating temperature |

-20 to + 60oC (Water: 0 to 40 oC) |

|||||||||||

|

Material |

Poly Urethane |

|||||||||||

|

(2) Color |

(3) The length of each roll |

||||

| Symbol

|

Color |

Symbol |

Color |

Symbol |

Length |

| B | Black | GR1 | Grey 1 |

20 |

Cuộn 20 m |

| W | Opalescent | GR2 | Grey 2 |

100 |

Cuộn 100 m |

| R | Red transparent | P1 | pink | ||

| Clear blue | PU1 | Dark purple | |||

| Y | Transparent yellow | PU2 | Purple transparent | ||

| G | Green transparent | R1 | Dark red 1 | ||

| C | Opalescent | R2 | Dark red 3 | ||

| YR | Orange | S1 | Silver | ||

| BU1 | Dark blue 1 | Y1 | yellow 1 | ||

| BU2 | Dark blue 2 | Y2 | yellow 2 | ||

| BU3 | Dark blue 3 | Y3 | yellow 3 | ||

| BR1 | Dark brown 1 | YR1 | Orange 1 | ||

| G1 | Green 1 | YR2 | Orange 2 | ||

| G2 | Green 2 | ||||

| G3 | Green 3 | ||||

| G4 | Green 4 | ||||

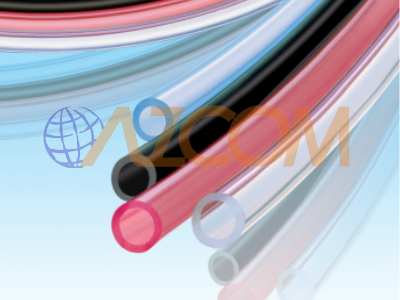

Polyurethane tubing is the ideal pipe for pneumatic applications. It combines the elasticity of rubber with chemical resistance that is usually specific to plastics. Polyurethanes can be divided into two distinct categories, ester bases and ethers.

Ethylene-based ethane is a hose material suitable for pneumatic applications due to its anti-hydrolytic properties and its high resistance to mold and corrosion. The ester-based polyethylene is a more durable compound but hydrolyses in humid environments. This hydrolysis process will degrade the material over time.

SMC’s main Polyurethane tube is an ether base type, made from the finest quality compound available to ensure the longest duct life; with characteristics: Anti-cut off; Format bear; Wide heat resistance range; Low elongation; Low air permeability; Anti-folding pipe; Anti-tearing; Wear resistant roofs; High elasticity; Anti-chemical agent